Analysis of dissolved gases (DGA) plays an unparalleled role in ensuring the longevity and reliability of transformer equipment. This method of diagnostics allows for the identification of potential problems at early stages, which is critically important for preventing possible emergency situations and extending lifespan transformers. In the modern world, where reliable and efficient energy systems acquire more significance, deep understanding and application of DGA are integral parts of successful strategy asset management. Learn more about transformers service and repair.

Innovative Foundations Reliability Transformers with Analysis Dissolved Gases

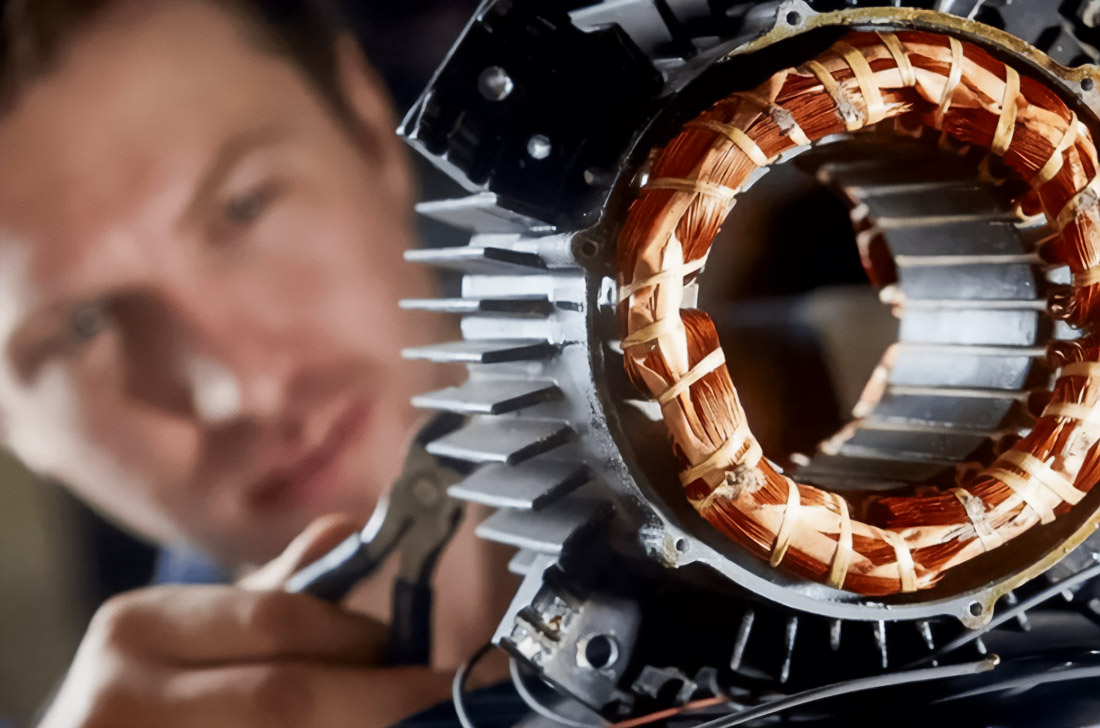

Process analysis dissolved gases (DGA) consist of study gases, which dissolve in transformer oil. In conditions of normal operation, transformers form various gas compounds; however, in case malfunctions occur, such as overheating or electrical discharge, their concentration may significantly increase. DGA allows, with high accuracy, to determine these changes, which gives the opportunity to assess the current condition of the transformer. This is — an integral part of preventive maintenance, which can not only identify the current condition of equipment but also predict its further operation.

Understanding Processes DGA: From Basics to Expertise

Procedure DGA begins with sampling oil from the transformer, which requires high accuracy for obtaining reliable results. Then, with the help of a gas chromatograph, a thorough analysis of composition gases, usually stand-out components such as hydrogen (H2), methane (CH4), ethane (C2H6), ethylene (C2H4), acetylene (C2H2), carbon dioxide (CO2) and oxygen (O2). Each of these gases may indicate certain types of malfunctions:

- Hydrogen (H2): Increased concentration may indicate beginning thermal decomposition.

- Acetylene (C2H2): Often indicates presence electrical discharge in windings transformer.

- Ethylene (C2H4): May signal high-temperature processes.

Key Stages and Principles Procedure DGA

DGA serves as a powerful tool for accurate diagnostics of various kinds of malfunctions transformers. For example, high concentration methane (CH4) and ethane (C2H6) may indicate low-temperature overheating casing transformer, while the presence of ethylene (C2H4) and acetylene (C2H2) may indicate more serious high-temperature processes or electrical discharges inside the device. Modern diagnostic models and algorithms, including method Duval and analysis ratios gases, allow specialists to more accurately determine type and localization malfunctions.

Diagnostics Malfunctions: Use DGA in Practice

The Key advantage of the application DGA lies in increasing the reliability and efficiency of the operation of energy systems. Regular conduction analysis of dissolved gases helps identify malfunctions at early, less costly stages, minimizing risk emergencies and downtime. This approach not only extends the lifespan of equipment but also significantly reduces costs for the repair and maintenance of transformers. Using DGA actively contributes to the optimization of the operation itself, allowing more accurate management of load and reducing energy losses. To learn more about increase reliability energy systems, visit this source.

Advantages and Benefits from Application DGA in Energy

For successful integration of DGA in programs’ technical maintenance and monitoring, it is recommended to establish standardized procedures for sampling and analysis of samples. Training personnel on the correct interpretation of data is critically necessary for increased accuracy diagnostics. Integration monitoring systems for automation process collection and analysis of data also play an important role. Modern technologies, such as the Internet of Things (IoT) and big data, simplify and accelerate these processes, improving overall efficiency. Learn more about integration IoT in energy systems here.

Practical Implementation DGA: Recommendations and Strategies

Numerous successful cases demonstrate the effectiveness of DGA in practice. For example, one of the leading energy companies implemented regular analyses of dissolved gases in its comprehensive technical maintenance transformers program. This allowed for timely identification of potential malfunctions and prevented serious emergencies. Results led to significant reduction costs for repair and improvement reliability operation of their energy system.

Analysis of dissolved gases (DGA) became the cornerstone of modern strategy management transformer equipment. It provides an invaluable opportunity not only to identify and prevent malfunctions at early stages but also to optimize operation energy systems in general. In conditions of increasing demand for reliable and efficient energy systems, the influence of the application of DGA becomes more noticeable and necessary. Specialists capable apply this method in practice possess significant competitive advantage, contributing increase reliability and efficiency in the energy sector.

Basketball fan, shiba-inu lover, drummer, International Swiss style practitioner and independent Art Director. Acting at the crossroads of modernism and computer science to create strong, lasting and remarkable design. Nothing ventured, nothing gained.